- Contact Person : Ms. Lee Queen

- Company Name : Zhaoqing Bangli Building Material Industry Co., Ltd.

- Tel : 0086-758-3603059

- Fax : 0086-758-3603092

- Address : Guangdong,Zhaoqing,No.1, Zhenglonger Street, Linjiang Industrial Park, High-tech Zone, Zhaoqing City.

- Country/Region : China

- Zip : 526238

aluminium cladding aluminium composite panel curtain wall aluminium cladding composite panel aluminium sandwish panel

aluminium cladding

Classified in purpose-a. For construction curtain wall The face and back plate thickness not less than 0.5mm, as well as the aggregate thickness not less than 4mm. Material of aluminum shall be qualified in accordance with the GB/T3880. Generally are adopting the 3000 or 5000 series aluminum alloy sheet, fluorocarbon resin for coating. b. For external decoration and advertisement

The face and back plate thickness not less than 0.2mm of rust-proof aluminum, as well as the aggregate thickness not less than 4mm, fluorocarbon or polyester for coating’s. Indoor use

The face and back plate thickness not less than 0.1mm of rust-proof aluminum, as well as the aggregate thickness not less than 3mm, polyester or acrylic acid for coating.

Classified in function a. Fire-proof plate Use antifoaming core, burning B1-class or non-ignitable A-class performance to meet international requirements of flame retardant materials’. Anti-bacteria

Take the antibacterial, antiseptic effect paint coating on Aluminum composite panel, make its have control microbial activity reproductive and eventually kill bacteria role’s. Anti-static electricity

Antistatic Aluminum composite panel adopts antistatic coating coated Aluminum composite panel, the surface resistivity in 109 below, than common Aluminum composite panel surface resistivity is small, so not easily produce static, air dust also not easy adherent on its surface.

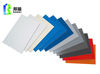

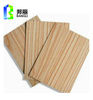

Classified in surface refinements a. Coating decoration In aluminum plate surface coated with all sorts of adornment coating. There is generally used fluorine carbon, polyester, acrylic coating, mainly including metal color, plain, wood color and stone color, ornamental function, is the most common market varieties. b. Heat tinting By anodic oxidation timely handling aluminum alloy panels with rosy, chic color, such as bronze makes special adornment effect. c. Color printing Different pattern through advanced computer printing technology, the color printing ink printing paper in print various copy is natural decorative pattern, and then through sublimation technology indirect Aluminum composite panel on the duplicate of all sorts of copy natural pattern. Can satisfy the designer's creativity and owner personalized choices.d. Wire drawing Adopt surface is drawing processing of aluminum alloy panels, common is gold and silver wire drawing products, bring different visual perception to suffer.e. Mirror surface Aluminum alloy panels with surface polish, like mirror.

Performance

Strong stripping degrees-Aluminum composite panel adopted new process that the key technology of aluminum material peel strength, improve the indices to excellent condition. The flatness, weatherproof aluminum material properties are increased accordingly.

Material easily processing-Aluminum composite panel, every square metre around 3.5-5.5 kg weight, it can reduce the damage caused by the earthquake disasters, and easy to handle. Its superior construction by simply carpentry tool can finished cutting, clipping, planer edge, arced, right angle and kinds of style, can cooperate design personnel, making changes, easy installation and quickly, also reduced the construction cost.

Fire performance excellence-Aluminum composite panel is among flame retardant material PE plastic core material, both sides are extremely difficult to burning aluminum layer. Therefore, it is a safe and fireproof material, accord with building regulations of refractory needs.

Excellent resistance to impact-Impact resistance, high toughness, bending loss topcoat, resistance to impact, strong in sand larger districts also won't appear because of sand cause damage.

Super weatherability-Because used to KYNAR - 500 base makings of PVDF of fluor-carbon painting, have weatherability, no matter in a unique advantage,the hot sun or cold in the wind and snow are nondestructive in beautiful exterior, can reach 20 years does not fade.

Uniform coating, color diversity-After atomization treatment and the application of Henkel technology, it makes the paint and aluminum composite panel to improve adhesion of the uniform, color diversity, allow you choose larger space, all show you’re personalized.

Easy maintenance-Aluminum composite panel in resistance pollution aspect have been significantly improved. China's urban environment pollution is relatively serious, using a few years need maintenance and cleaning, because good from self-cleaning need to use neutral detergent and rinsing, cleaning after plank permanent like new.

Fireproofing Aluminum composite panel-The ministry of public security and ministry of construction joint mandate regulation in Dec.2009: the 100 meters height above the housing exterior insulation material combustion performance should achieve A level (non-combustible material), Highly greater than or equal to 24 meters less than 50 meters of other civil building, Its heat preservation material combustion performance should be A grade or B1 level (flame retardant materials). Meet the national requirements class A and B1 standard insulation materials, be in usually not easily combustion, even if a Mars unapt also trigger recent domestic several times so serious fires. So strictly building materials fire performance, it is to build civil building "life firewall" the important link section. If let quality unmet of construction materials and heat preservation material used in construction, it is with the safe hidden trouble floor of increased and heighten.

Aluminum composite panel completely accord with standard of GB/T17748-2008, fire prevention reach B1 level, fluorine carbon aluminum composite panel quality can be maintained 20 years changeless.Smooth polished surface, excellent matchless formability, durable luxuriant appearance of the surface coating, simple and rapid processing installation, and preeminent fireproof performance.

aluminium cladding aluminium composite panel curtain wall aluminium cladding composite panel aluminium sandwish panel